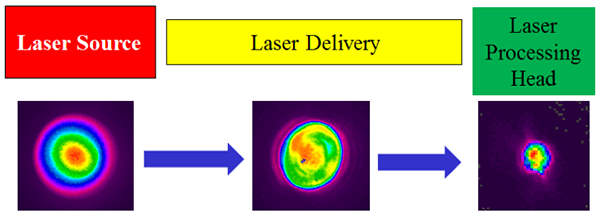

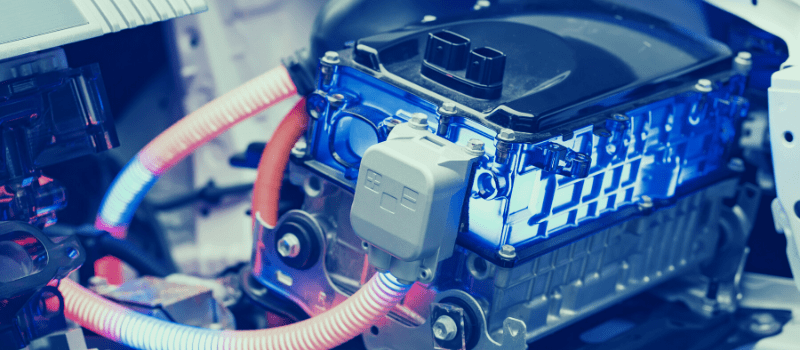

An aerospace company contacted us recently about their new metal powder bed selective laser melting (SLM) system. They were searching for reliable test and measurement equipment they could use in order to be sure their new SLM laser was functioning correctly.

In particular, they were interested to monitor their system for unusual focal shift, increased waist diameter, and M2 (beam quality) parameters.

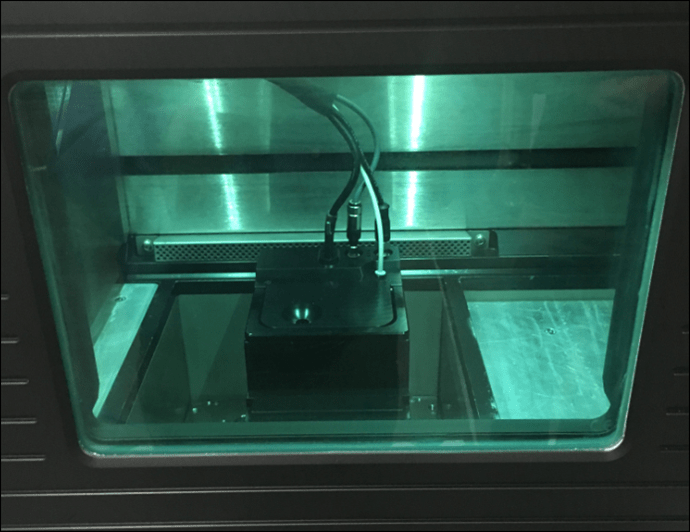

Ophir field service engineers showed them BeamWatch AM, which is a compact version of BeamWatch designed specifically for additive manufacturing use cases. BeamWatch AM uses Rayleigh scattering to monitor the entire beam caustic in real time (at video rates). This means the aerospace company can see whether the beam size changes during power up.

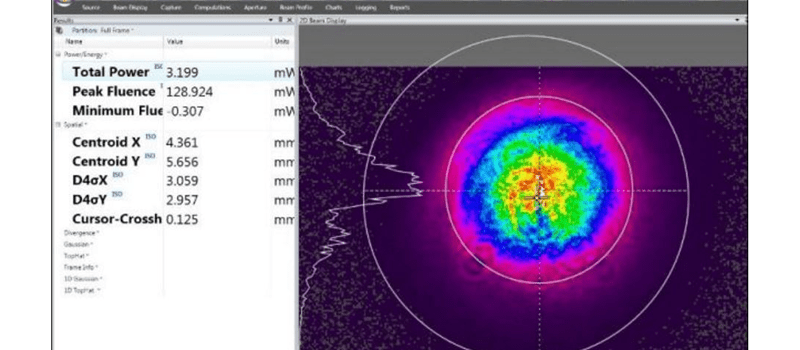

BeamWatch AM also provides them all the usual beam parameters, such as:

- Focal spot size and location

- Focal shift

- Centroid

- M2

- Divergence

- Rayleigh length

- Tilt angle

The aerospace company now uses BeamWatch AM routinely, resting assured that their SLM laser is operating as it should.

Leave a Reply

Your email address will not be published. Required fields are marked *