Today’s various laser applications, from delicate medical operations to heavy material processing, demand high quality laser beams which perform precisely and consistently. In order to ensure a laser is performing properly and efficiently it is necessary to monitor the laser performance using laser measurement devices. Although in some cases it is sufficient to use a laser power meter including a sensor to monitor laser power output, for many cases a beam profiler is necessary to measure as well the beam’s spatial characteristics such as: beam size, shape, intensity, and divergence. Knowing all of the characteristics of a beam could save a user a lot of time and money. In this article we demonstrate with several real examples how Ophir Spiricon and Photon beam profilers and software are used for different applications.

Laser marking

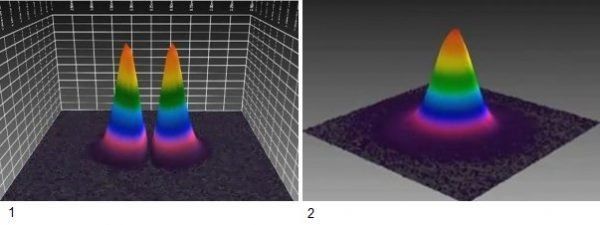

Laser marking requires a near Gaussian laser beam in order to obtain precise fine marks. Figure 1 shows a malfunctioning industrial ND: YAG laser beam, which was marking unreadable serial numbers on medical devices because of its deformed two peak beam profile. Even though the power output of the laser was correct, the laser was not aligned properly and therefore didn’t mark properly. Figure 2 shows the beam profile after a Gaussian beam was restored. Without measuring the beam profile with a beam profiler the users would not know why their laser wasn’t performing as they expected.

Laser welding

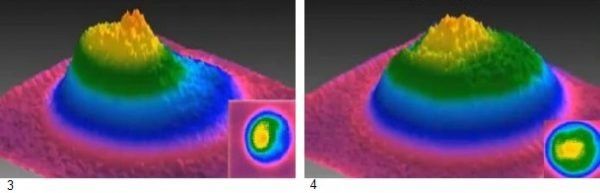

Since the laser is a highly concentrated heat source it allows narrow deep welding joints. Figure 3 shows a CO2 laser which was producing poor welding joints because its beam was highly asymmetrical. By simply aligning the laser cavity mirrors the beam was corrected in less than 10 minutes. Figure 4 shows the corrected beam. In this case the beam profiler helped the laser user reduce waste, shorten process work time, and improved the welding quality.

Adjusting a beam’s mode

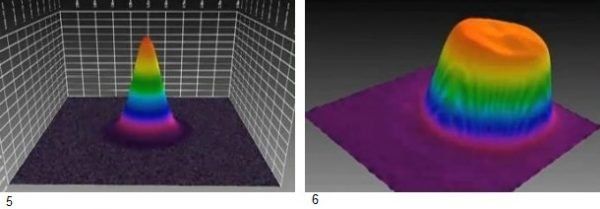

Some laser applications require a beam mode other than a Gaussian mode. For example, a flat top beam is required for tattoo removal during which the laser beam penetrates uniformly on the skin surface. Flat top beams are also required for many welding applications. Figure 5 and 6 show a flat top laser beam used for joining thin foils during a manufacturing process. Figure 5 is the original Gaussian laser beam profile, and figure 6 is the beam after it was adjusted by optics to achieve a flat top laser beam. The beam profiler was used to streamline the laser manufacturing process, efficiently ensuring the laser beam was a flat top beam.

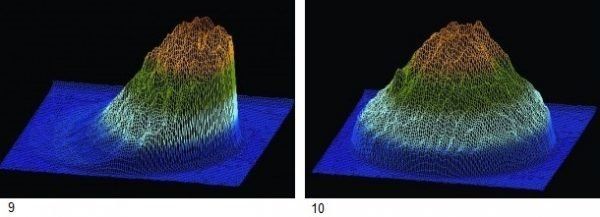

Aligning optics

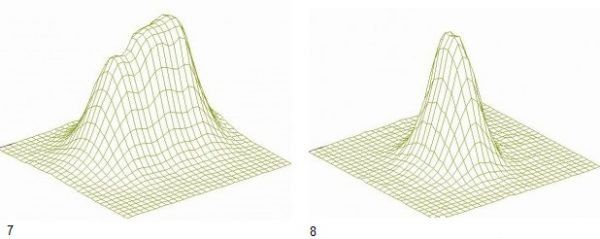

Beam profilers can also be used to easily and quickly align optics. For example, figure 7&8 show beam profiles during alignment of a collimating lens to a laser diode. The first profile shows poor alignment of the lens to the diode, which can easily and quickly be improved when seeing the profile in real time. Similarly, Figure 9&10 show an industrial ND: YAG laser with misaligned turning mirrors, before and after adjustment.

Ophir Spiricon and Photon offers a variety of beam profilers, including: CCD cameras, scanning slits, InGaAs and pyroelectric arrays. The proper choice of a beam profiler depends on beam wavelength, beam power, beam size, continuous or pulsed.

You might also like to read:

Medical Laser Applications: Beam Measuring & Profiling

Beam Profile of Dental LED Curing Units

Share This:

Leave a Reply

Your email address will not be published. Required fields are marked *