CCD and Scanning-Slit Beam Profilers

Many people will profess to speak the truth, but few are really in a position to be completely impartial. I’m not saying that everyone is a liar, but try asking someone who sells camera beam profilers to tell you the difference between them and their scanning slit counterparts. He may not lie outright, and he may not even realize what he’s doing, but his views will almost certainly be slanted. He will, almost automatically, highlight the problems with scanning slit beam profilers while he minimizes the issues with a camera.

Ophir is in a great position to arbitrate this case. Since we sell both kinds of laser beam profilers, you can expect to have a fair argument on each side. I’ll provide both the good and the bad.

In engineering school, one of my teachers pointed out that the very existence of more than one method means that the perfect solution does not (yet) exist. This is true in a myriad of contexts, but laser beam profilers is certainly a good example. If you hear a scanning slit provider try to convince you that there is no aspect in which cameras are superior, you must ask yourself: “Why, then, would anyone use a camera?”

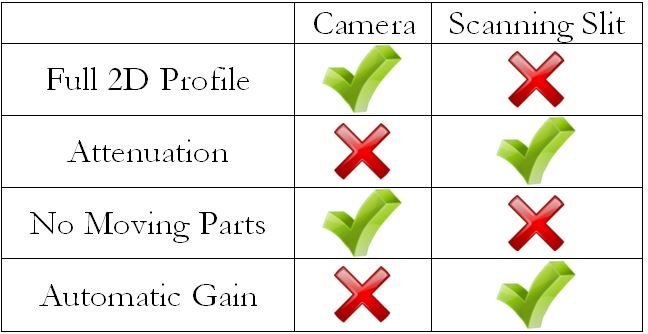

So, let’s get to it. Here’s what I think are the (basic) pros and cons of each beam profiling method. (Did I miss any? Let me know in the comments.)

Cameras[1]

Real 2D profile: Aside from providing information like beam width along each axis, a camera provides the unique ability to truly SEE the distribution of power (or energy) across your beam.

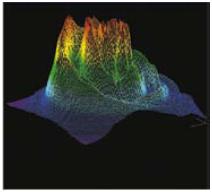

This CO2 laser is a good example of a case where one might need to see the complete 2D profile to understand the source of the problem. (In this case, inconsistent industrial processing.)

Profile of a CO2 Industrial Laser

Almost always requires additional attenuation. Saturation intensity is typically in the range of a few μW/cm2 (above which the reading will be incorrect, although the laser probably won’t damage the sensor unless it’s much higher).

Scanning Slit Profiler

No attenuation required. Of course, this isn’t always true, but it’s certainly the case for most situations. A Pyroelectric NanoScan, for example, can profile beams up to 100W without any attenuation.

Automatic gain: Another benefit of this natural attenuation is that automatic gain becomes a viable option. This feature is crucial to an optical feedback setup, as just one example.

1D profile: A scanning slit actually profiles on each axis, but misses the information in between. This means that it can – very accurately, I might add – measure the beam width, divergence and other related parameters. It cannot highlight hot spots or other beam distribution discrepancies the way that a camera can.[2]

Moving parts: In order to scan the laser beam, you need a motor that moves the slit (hence, scanning slit). The addition of moving parts means a greater complexity and, typically, a higher price.

Quick Summary – Have you been paying attention?

Okay…

So, which one is it?

Should I get a camera or a scanning slit?

As you can guess from the pros and cons above, it depends on your laser and how you intend to measure it.

Say it’s a very high power laser and you just need an accurate beam width – NanoScan is very probably the solution. It’s worth emphasizing that the lack of a 2D profile does nothing to impair a scanning slit’s accuracy in other measurements (such as beam width, divergence, etc., as we said above).

On the other hand, if you’re more interested in checking the full profile of the laser beam – if you want to see how close it is to a Gaussian, for example – you might prefer the CCD profiler.

Of course, a full comparison is really much more nuanced and beyond the scope of the post. I hope I’ve given you a bit of background, but certainly talk to a laser measurement representative to help you find the best beam profiler for your needs.

[1] By cameras I mean any type of detector array, including not only Silicon, but also InGaAs and Pyroelectric detectors.

[2] A scanning slit can see hot spots, but the detail is lost in the slit integration. As in most complicated situations, nothing is black-and-white.

Wonderful image; thank you Seth! I love the caption. From now on, if you’re feeling low, add the word “fashionable” to a sentence and just like that you’ll feel better. Also, the abbreviation “Conn” is much nicer than today’s underwhelming “CT”. I use Conn just to kick it old school, but outside of the Wall Street Journal, you just don’t see this much.