LED’s are used today in many applications with the most prominent being the lighting of our homes, streets and businesses. Despite their clear advantages, measurement techniques of the power, flux and spectrum of LEDs is not very different from that of traditional types of lamps.

A typical setup for measuring the power of LEDs and LED modules includes the following items:

- An integrating sphere. Typically 50cm to 1m in diameter is recommended.

- A spectrometer.

- A fiber connecting the spectrometer and the sphere.

- A calibration lamp (recalibration is required after 50 hours)

- A low noise, fixed current power supply for the calibration lamp.

- An auxiliary lamp for self-absorption calibration

Such a system can measure the total flux in Watts, Lumens, the spectral flux in Watt per nm, and various photometric quantities such as CCT (correlated color temperature) and CRI (color rendering index).

The cost of even an entry level system can reach $10,000 and the accuracy of such a system is ~5%-10%. Higher accuracies require much more expensive systems.

In addition to the high cost, the use of such a system is not simple. The system has to be calibrated frequently, and with every measurement, a self-absorption calibration has to be done. The self-absorption calibration corrects for the fact that the measured LED changes the geometry of the integrating sphere and affects the calibration.

Measuring LED power using a thermal disk sensor

In some measurement applications, only the total power in Watts needs to be measured. In those cases a thermal disc sensor may be used if the following conditions are met.

- The light source is small (<20mm) or can be focused to a small spot.

- The light source only emits forward (beam divergence up to ±70°)

- The light source has a power of >40mW

The thermal disc sensor has several advantages which make it a good choice for measuring power of LEDs:

- Flat spectral response from 190nm to 20µm. The thermal disc is coated with a black absorber which has a very broadband and flat spectral response. This means that it will measure the incident power in Watts regardless of the wavelength and bandwidth of radiation.

- The response is angle insensitive. Unlike photodiode detectors whose responsivity decreases for light at high angles of incidence, the absorber on the thermal disc is angle insensitive. This means that the thermal disc sensor will not discriminate beams with high divergence angles.

- High damage threshold. Thermal disc sensors can hold up to more than 100W of incident power.

- The price of a thermal disc sensor is a fraction of a comparable integrating sphere system.

- Accuracy. Typically ±3%, NIST traceable.

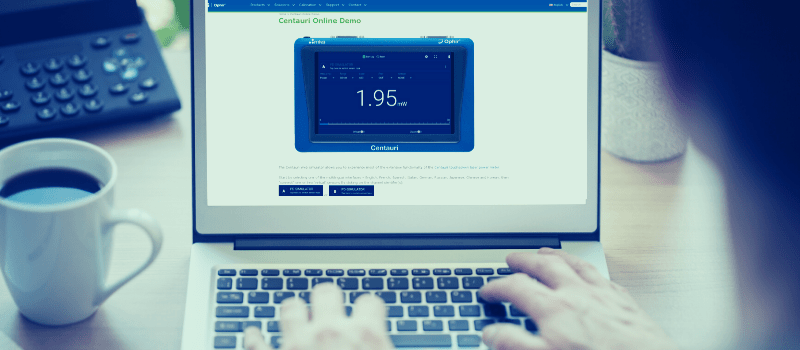

Using the thermal disc sensor is much easier compared with the integrating sphere system. Just point the LED light beam onto the sensor and the power measurement will appear on the meter or your screen. Routine calibration is on a yearly basis.

Figure 1. shows a measurement setup where a fiber is used to deliver LED light. The fiber is pointed at the thermal disk sensor for a measurement of the total power delivered from the LED:

Leave a Reply

Your email address will not be published. Required fields are marked *