Many laser systems have beams propagating through several stages before the final beam is directed to its target. Monitoring laser performance of these systems is important but may be difficult.

For example, a system may include a 532 Q-switched laser pumping a Ti: Sapphire 800 nm laser or another setup where one laser is pumping another. In order to ensure high efficiency of the system, it is necessary to measure the pumping efficiency, the ratio between the pumping beam and the output beam. Another example is where two pulsed lasers are interleaved to increase the effective repetition frequency and energy throughput of a system. To ensure the interleaving is done correctly it is necessary to measure each of the beams separately, sum their powers, and measure the interleaved output to make sure it is equal to the sum. These systems and other laser systems with sophisticated optical setups require an efficient, easy to use, and fast monitoring method.

Although in some optical setups it may possible to measure each parameter sequentially, with one sensor, manually logging the results and then calculating data, this would not be an efficient method. Manual logging is time consuming and does not enable real-time monitoring. It is risky to analyze the measurements manually.

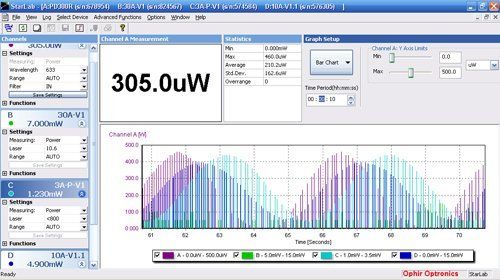

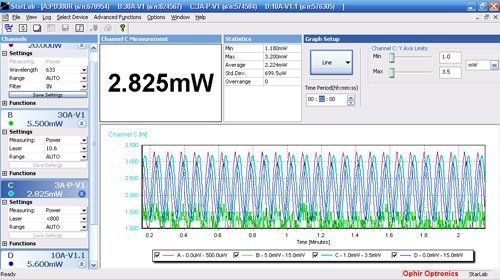

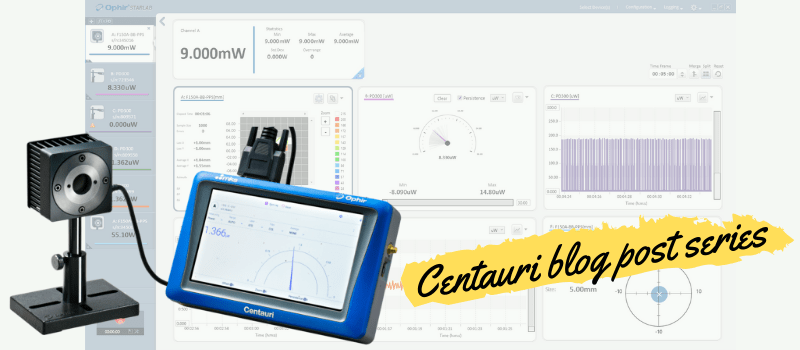

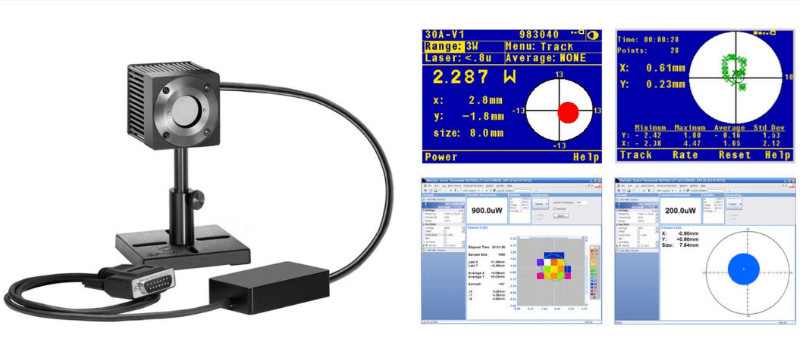

Ophir offers laser measuring devices and software that enable efficient measurement of a beam in several junctions simultaneously and quickly by using a PC. By simply placing sensors at every strategic junction on the laser, feeding the sensors with a fraction of the beams through beam splitters, and connecting them to the PC, the system is set up for multiple, real time, simultaneous laser measurements. By running Ophir’s Starlab software, the information from all sensors is displayed and logged on the PC to provide temporal graphs of all channels. The time stamps of the various channels are synchronized, so a user may tell how the beams perform in time relative to each other. Furthermore, Starlab allows the use of mathematical functions between sensor data. Hence, the pump efficiency as well as the ratio or other combination of two separate beams could be monitored automatically and quickly. These features allow quick diagnostics and/or production tests after an initial set up.

Ophir’s StarLab can interface with various Ophir devices that connect to Ophir sensors. This includes the Juno USB interface, USB connections on Power/Energy meters and the Quasar Bluetooth wireless interface. Each of these may be logged on to a PC quickly and easily.

Please feel free to comment an add things you have on your list

You might also like to read: Analyze your beam measurements using Matlab!

Share this:

Leave a Reply

Your email address will not be published. Required fields are marked *