Laser welding, cutting, or cladding has become increasingly popular and, in most cases, has been performed at the NIR wavelength region.

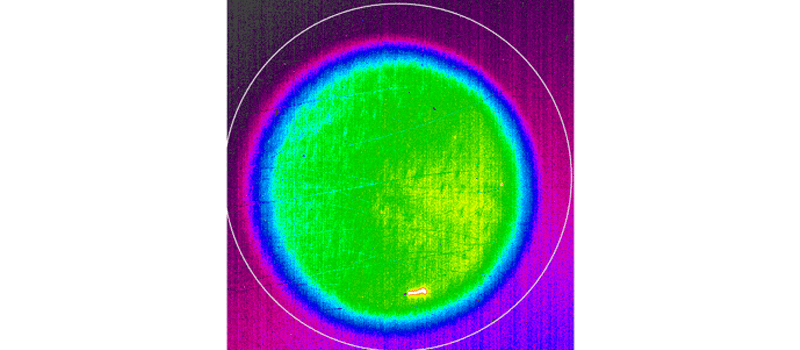

However, NIR lasers are less efficient for copper processing due to high reflectivity and therefore low energy absorption.

Copper absorbs just 5% of the laser energy at 1070nm, but up to 40 % at 515nm, and about 65% at 450nm. Operation in green or blue wavelengths allow the use of significantly less power to achieve the same welding results.

Lower laser power also creates less spattering and, as a result, fewer defects which contributes to the repeatability and quality of the process.

Using shorter wavelengths also enables the creation of smaller focal spots, resulting in deeper laser penetration inside the substrate and enabling a more rapid welding process.

Recently, several leading producers of material processing lasers have introduced green and blue high-power lasers designated for welding copper foils in battery cells.

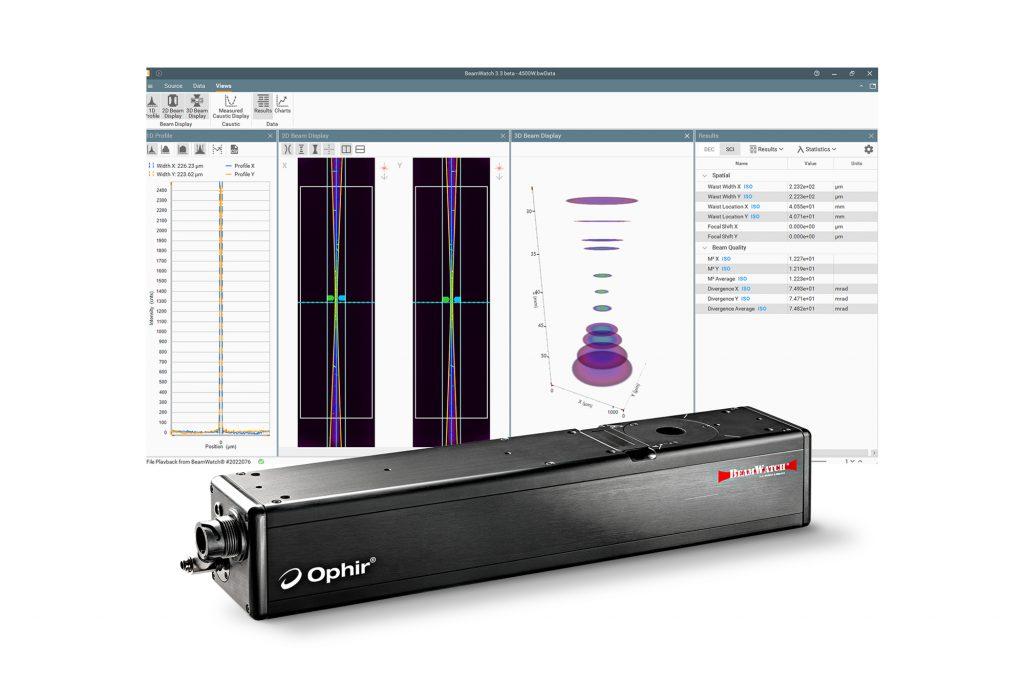

BeamWatch Plus

To keep pace with industry developments, Ophir updated its contactless high-power laser beam profiler.

The new BeamWatch PLUS can characterize high-power lasers operating in both VIS wavelengths (420 – 635nm), primarily green and blue lasers and in the NIR region (950 – 1100nm).

To support smaller focal spots, the minimum measurable laser waist size was reduced to 45µm, and the overall instrument accuracy was increased.

Real Time Beam Characterization

The BeamWatch PLUS is capable of providing simultaneous and real-time measurement of all industry-required parameters, including focus spot (waist) width and location, focal shift, M2, divergence, Rayleigh length and tilt angle.

The device uses a contactless measurement method, based on Rayleigh scattering, eliminating laser beam distortion by optical components and damage to the instrument. It also enables the measurement of high-power lasers without upper power threshold.

BeamWatch PLUS provides instantaneous measurements, enabling beam monitoring at frequent intervals, without having to shut down the process or remove the tool.

The BeamWatch software provides a real time accurate analysis of laser waist size and position, focal shift, M2, divergence and other parameters essential for industrial laser applications.

Leave a Reply

Your email address will not be published. Required fields are marked *