Mike Martino, founder of BlackBox Technologies, shared his experiences of finding a solution for Sheaumann Laser Inc. who requested of BlackBox to create a reliable power meter solution for testing their high power laser diodes.

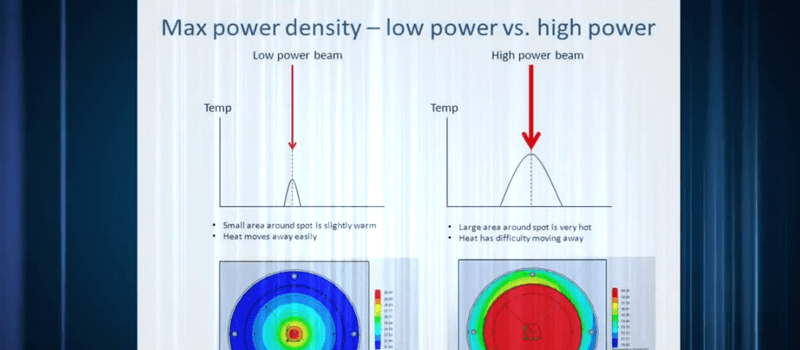

There were many challenges that needed to be considered in regards to the application. First of all, it required a specific wavelength at a specific power level. To achieve this, the temperature needed to be controlled since even the smallest change in temperature would create a shift in laser output power which would lead to a small but meaningful change in wavelength. This could totally throw off the feasibility of the laser application.

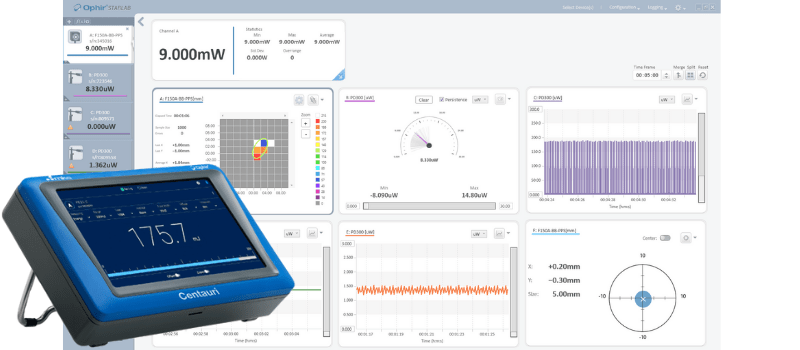

Also, in some constant wave (CW) applications, the required output power from the laser pushes the laser’s maximum specifications but even so, the testing must be done that those levels. The optical power meter needed to have interchangeability with power heads of varying power level capability, have full calibration traceability, and integrate well with the test equipment computer. They needed a laser meter where the laser current could be set and then there was a predefined waiting period in order to allow stabilization of temperature and power.

The Ophir Nova II Series and the laser high power air-cooled thermopile fit BlackBox’s needs.

BlackBox Technologies ended up developing a marketable high power laser diode power meter that is accurate, stable, and with repeatable results. The system also incorporates extensive safety measures including interlocks and is compliant with applicable ANSI specifications.

A wide range of high power laser diodes are being developing to be used in many different applications. Power meters need to be developed to fit all the different kinds of lasers which often have many differences between them from different power levels to different shapes and sizes. In order for the laser monitoring to be effective, the testing needs to happen at the wavelength and power levels at which the application will be used. The meter also needs to be “low drift” meaning, that it stays accurate for a long time.

Read more about BlackBox’s use of Ophir power meters to create customized solutions for testing high power laser diodes.

Please feel free to comment and add things you have on your list

You might also like to read: How Can High Power Laser Measurement Sensors (1-10KW) Be Calibrated By Laser Measurement Vendors?

Share this:

Leave a Reply

Your email address will not be published. Required fields are marked *