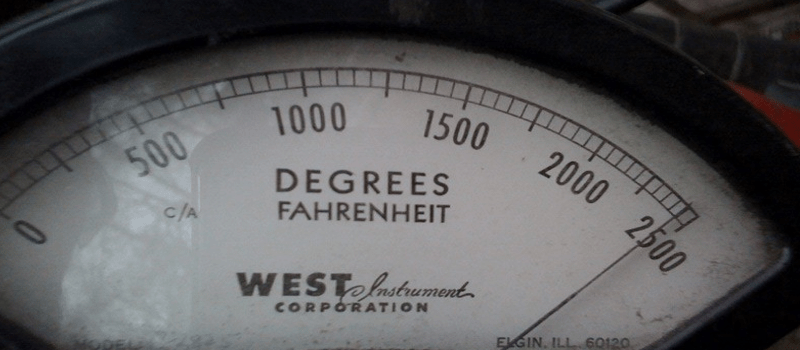

Many people do not understand the necessity of equipment calibration. They do not understand what the calibration process entails, and how it can save them money, time, and frustration.

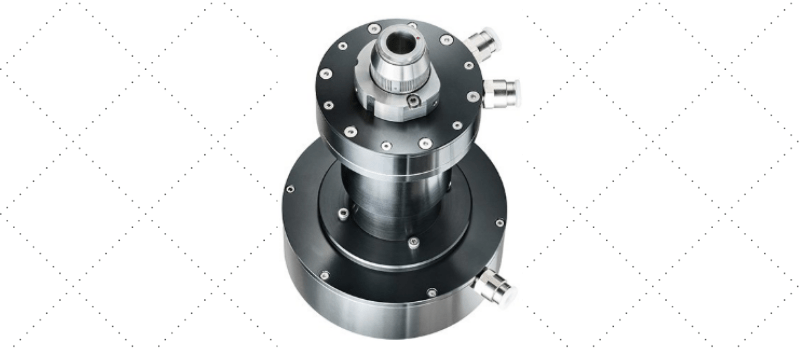

Ophir’s products are used throughout the world in many different areas, from medical and scientific processes to defense and industrial applications. With each application there are different usage parameters.

However, one thing that remains consistent no matter the application – is that when your equipment is properly calibrated, you can detect problems before they impact your customers. This translates to higher quality product produced, more accurate results for testing, and increased customer and patient confidence and loyalty.

What happens during the calibration process? What happens in cases where the equipment is not functioning properly?

How can properly calibrated equipment help maximize resources (time, energy, or materials) and reduce costs? Read more: https://www.ophiropt.com/laser–measurement/knowledge-center/article/9196

Leave a Reply

Your email address will not be published. Required fields are marked *