If you have been in the laser cutting business long enough you eventually will have one of those days when, no matter what you do, the laser will not cut your parts cleanly…if at all. The operators and maintenance personnel check and verify all the usual problem areas and finally conclude that everything looks, measures, and appears correct.

Most checks and verifications are really just a moment in time, but the moment in time that you check may not be the same moment in time when the problem arises. The laser beam quality is the single most important characteristic that determines your laser’s ability to process material at peak performance. Taking a beam mode shot into an acrylic block lasts only a couple of seconds, but laser cutting a part may last several minutes.

Therefore, when service technicians or maintenance personnel replace optics or tune the mirrors in the resonator, it is a difficult task to view a beam profile with the same properties as a beam that is hot and causing thermal lensing.

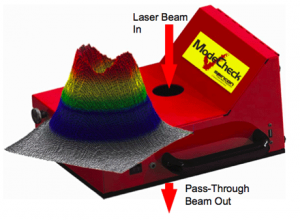

A laser beam profiler displays the spatial profile of a laser beam at a particular plane transverse to the beam propagation path. The good news is that laser beam profilers are reasonably priced tools that allow us to look at the beam instantaneously and display variations as they occur versus hope that we take a shot at the right moment.

Recently, this exact scenario occurred at a customer site. In the past, optics would have been replaced one at a time until the cutting conditions improved. Seems simple but the systems have 10-15 optics each and testing and beam realignment between each optic change could take days to complete. This results in a loss of production, increased price from service technician labor rates, and the cost of 10-15 optics to replace one bad optic.

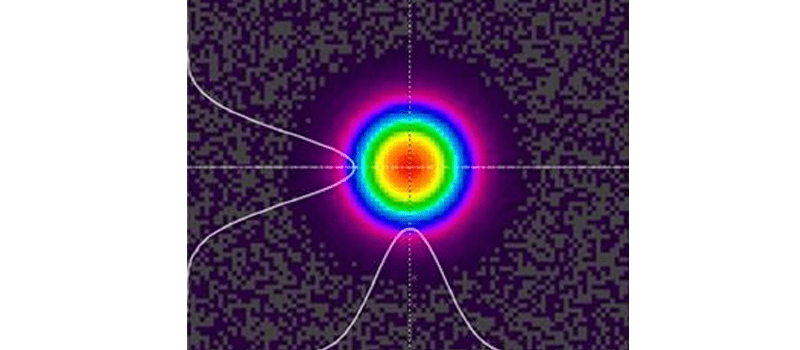

I tested Ophir-Spiricon’s ModeCheck® profiler recently and found the device invaluable. The above scenario is just one of many of its benefits. The setup was quick, the data captured was accurate, and the display of the beam profile updated quickly with the tuning process. Once I gained confidence data gathering and saving profiles, I decided to put the device to the real test. If you have multiple laser systems that are identical except one laser always outperforms the other, the question is, “What’s different?” Mode burn blocks are open to subjective interpretation because of the melted edges around the diameter of the profile shot. Calculating power density and accurately measuring beam diameter, laser beam width , beam depth, and symmetry are challenging without ModeCheck. With ModeCheck, the saved data contains all the information in one electronic location…no need to label acrylic blocks in one location and data in another.

The test finally answered an age old question. As the under-achieving laser beam profile passed through ModeCheck, the profile began changing from a round beam to a slightly elliptical shape and then back to round as the laser heated up. A laser with an elliptical beam profile will have a wider cut along one direction than the other. The elliptical mode, in return, will generate a wider focused spot through the cutting lens, reducing power density. Power density is critical to processing speed and cut quality. The effect was small enough that it was not detectable in the acrylic block, yet was obvious in the ModeCheck display. ModeCheck proved to me that relying on the old acrylic block method for determining beam quality is a thing of the past.

By Todd Jacobson, Technical Consultant, Laser Maintenance Group, Corp.

You might also like to read:

Goodbye Acrylic Mode Burns, Hello ModeCheck Low-Cost CO2 Beam Profiler

Please feel free to comment and add things you have on your list

Share this:

Leave a Reply

Your email address will not be published. Required fields are marked *