Beam profiling in a nutshell

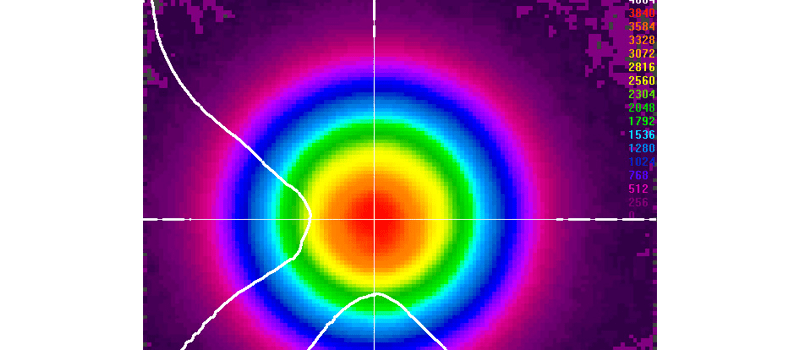

Take a look at these images:

You don’t have to be an expert to see that the six-month profile is less efficient than the factory one. These images show the natural degradation of a laser. It is through beam profiling that one would be aware that there are changes and know exactly what changes are happening.

In a nutshell, laser beam profiling shows you in images how the laser’s power is being distributed. The software that accompanies the imaging devices performs a myriad of measurement tasks, giving you a full picture of how your laser is working.

What’s wrong with the internal average power monitoring?

Most lasers come with internal average power monitoring but this monitoring is usually only part of what you need to know. If you only rely on the internal monitoring, there are many problems that could arise without you even knowing. A spatial measuring device is necessary in order to get a full and objective analysis and it will give you the information needed to make appropriate adjustments when necessary.

Don’t crank up the power!

It is only natural that there is degradation of your laser over time. Certain functions like weld penetration may not remain consistent. The question is, how do you deal with that?

Shop foremen who don’t use beam profiling solutions often say: “When the beam isn’t doing the job, we usually turn up the power.”

This does not work. Higher power does not necessarily mean higher beam quality. You don’t believe us? Check out the following images. Do you see which power level has the highest quality? Hint: It’s not the highest.

Cranking up the power any time your laser stops functioning properly will not solve the problem. The real problem isn’t being diagnosed and fixed which could be catastrophic in the long run. If, for example, the crystal or optics aren’t changed in time, it could mean huge loses of time and money.

more about the benefits of beam profiling.

To learn more about the pluses of beam profiling for your industrial laser, including how it can extend periods between maintenance, lower cost and make you into the laser troubleshooter of the company, read the industrial beam profiling article by John McCauley.

You might also like to read: The Mystery of the Laser Parts that Failed Inspection

Share this:

Leave a Reply

Your email address will not be published. Required fields are marked *