Recently, I had the opportunity to perform a product demonstration for a prospect.

I’d been in field sales for Ophir for about seven and a half years from 2009 to 2016, but with the pandemic limiting customer visits over the past several years combined with a recent role change, it had been a while since I’d had to set up and demonstrate our products in front of a customer.

So, I was a bit nervous with the thought of getting in front of a customer again and with all the possible pitfalls that come along with a visit like this. Did I know enough about the laser system ahead of time? Would I be showing the right equipment to them? Would my equipment work properly?

My experience with similar customer visits told me that anything could go wrong during my visit so my preparation for the visit was a little more involved this time than it had been in the past.

When it was all said and done, it was a lot like riding a bike.

Many of the concepts surrounding the performance of a laser are difficult to forget, but it was only because of my experiences with past demonstrations and perhaps not because these are obvious concepts. Speaking with the personnel present for the demonstration, who were relatively inexperienced with laser processing at this time, helped me realize that there are some things that you should familiarize yourself with before jumping into taking measurements on your laser. I thought it was worthy enough to summarize in an article.

Understand how a laser works

Even before selecting the equipment to best measure your laser performance characteristics, you should have a basic understanding of how your laser behaves as it will likely define which measurement products you will select. Is your laser continuous-wave (CW) or pulsed, and what is the difference? What is laser power? What is laser energy? And what is their relationship? What are the characteristics and ratings of your laser (wavelength(s), max power or energy, pulse characteristics such as pulse width, pulse frequency, pulse shape, etc.)?

Also, understanding how your laser will be used in the desired process is important. For example, if it’s an industrial laser used for material processing, your laser light will most likely be coming out of a processing head and converging to a focused spot at the process. Power Density is the measure of how much laser light is produced with respect to the beam size at the process and is usually expressed in “watts per centimeter squared (W/cm2).

It is important to know for sure:

1. how much laser light is being produced through a power or energy measurement, and

2. the focused spot size at the work site through a beam profile measurement. These two characteristics will define the Power Density of the laser being applied to the process.

Become familiar with your laser system.

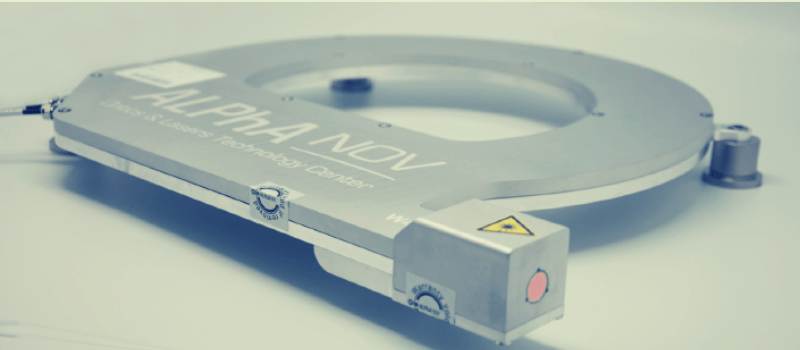

It’s not only the laser ratings that will define the measurement products you select. It will also be the physical characteristics of your entire laser system as well. While very helpful to consider laser measurement solutions during the design of a laser system so that these products can be integrated into the system, this is not always the case. Most times, measuring laser performance will be considered after the laser system is designed and commissioned.

In some cases, where the system restricts access to the laser light, measurement of the laser is impossible due to space constraints. When this is the case, the best practice is to consult with your local field sales engineer to ensure that the damage threshold ratings of the products that you are considering are not exceeded.

There may also be characteristics of your laser system which may make the setup of your measurement products somewhat less straight forward.

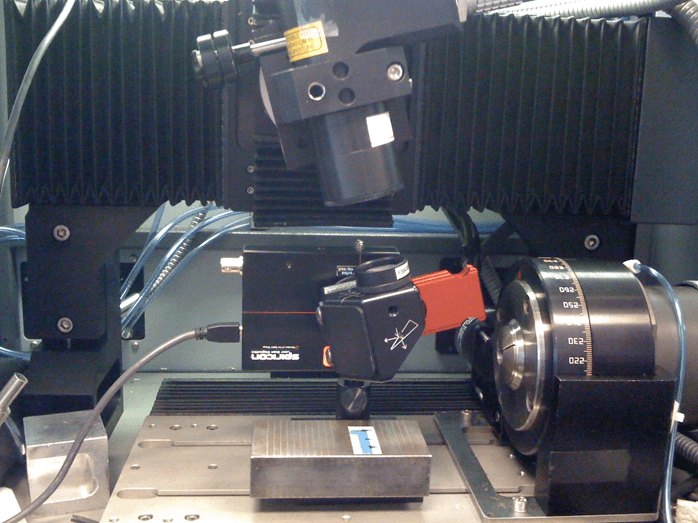

For example, many glovebox welding lasers have a processing head that is set at an offset, somewhere between 5 ͦ and 15 ͦ in most cases.

When setting up a beam profiling system for the first time on these laser systems, you must first find the correct X and Y locations so that the camera imager will image the beam.

Second, the correct Z height must be found so that the camera will image the beam at focus.

Third, the beam profiler’s attenuation device must be rotated at the same offset as the welding head so that the beam enters the input aperture at a perpendicular angle so that there the focused spot is not imaged with any false ellipticity measurements.

Know your measurement product limitations.

While Power Density is your friend as the laser is processing, it is your enemy when taking measurements. The basic concept when taking measurement is to not “process” your measurement products through exceeding its rated damage threshold by applying too high a Power Density. Something that is often misunderstood is the idea that a power or energy measurement must take place at focus so that “the most accurate measurement can be achieved”. This is not the case. Laser power or energy will be the same regardless of the size of the beam. But when the size of the beam is too small, Power Density increases exponentially, and will eventually exceed the damage threshold of the measurement equipment.

Understanding this concept is vital, not only when selecting measurement equipment, but also when using and maintaining the measurement equipment. Damage threshold ratings are included on all of our product specification sheets and should be strictly adhered to. As always, it’s also a good practice to involve a field sales engineer when selecting your equipment and setting it up for the first time.

No one will argue against the fact that the long-term success of your laser process will involve properly maintaining your laser system. The measurement of your laser within this system, and understanding how your laser light is behaving, both at that moment and over long periods of time, certainly adds to the success of the application and the maintenance of your laser system.

Selecting and setting up this measurement equipment can be daunting if basic laser characteristics and how these solutions relate to your laser and laser system are not understood.

Fortunately, these concepts are easy to understand and there are many resources available to help you understanding them.

The information that you will get from these measurement tools will be extremely valuable to you over the years.

Leave a Reply

Your email address will not be published. Required fields are marked *