When asking the SLM manufacturers and users about what they need to know about the laser beam, the first answer we mostly get is, the cross section of the beam profile. But sometimes, this is not the key to solving most problems.

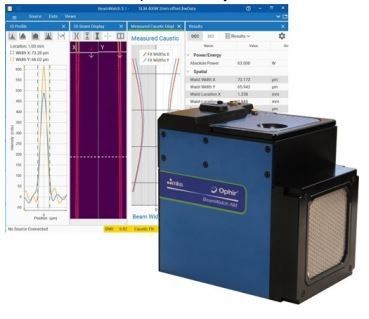

The following blog post offers examples of additive manufacturing systems troubleshooting using Ophir’s BeamWatch and BeamWatch AM Rayleigh Scattering measurement instruments.

To learn more about this method and background, please see our last week’s blog post.

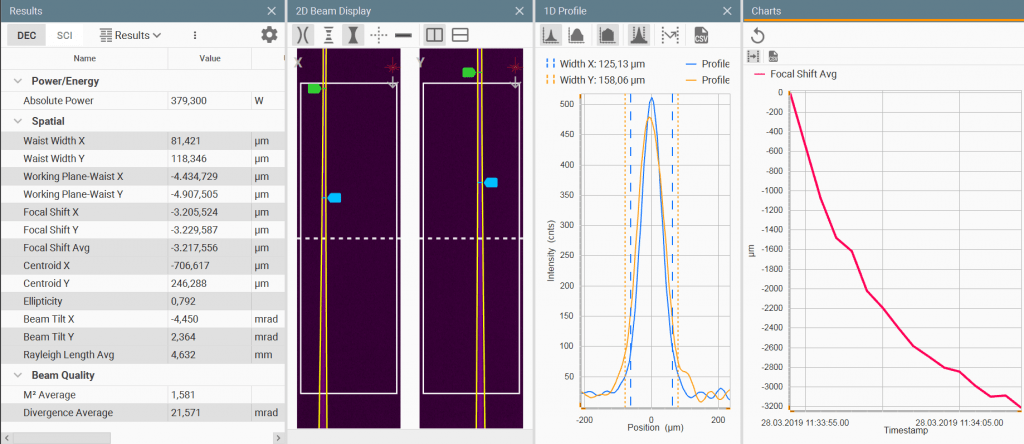

- After the appearance of quality problems, the measurements indicate a 3.2 mm focus shift within 15 seconds of process start which was detected by BeamWatch:

It was suspected that either some parts were not properly cooled, or that a lens or protective window might be damaged. The protective window looked clean, but after cleaning it the focal shift returned to 0.6mm

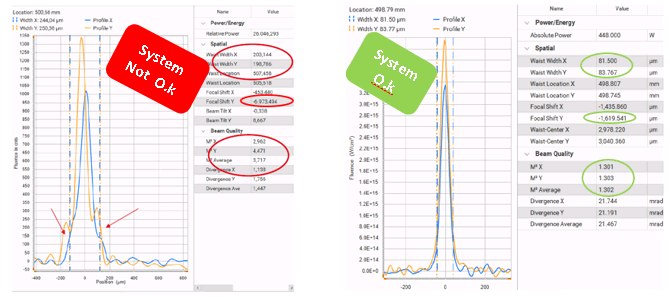

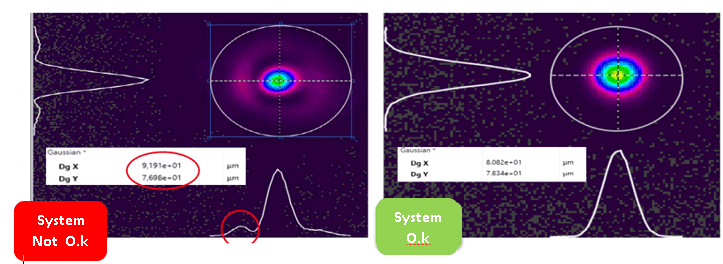

2. BeamWatch AM observed difference in High Focus Shift and a Non Gaussian distribution and asymmetrical deformation of the laser beam profile.

This caused enlarged focus in working plane and reduced power density resulting in highly porous product and strength problems.

Based on BeamWatch AM measurement, the operator was able to analyze that Beam delivery was poorly adjusted causing undesired irradiation of the component along the machining path so that part of the laser power was diverted resulting in diffraction and thermal effects.

In this case, compared to the real time caustic measurement done by BeamWatch AM the single cross section of classic Beam Profiling provides insufficient information for adequate troubleshooting;

Rayleigh Scattering based measurements enable the SLM system operator to promptly and accurately identify and isolate system malfunction without significant process delays.

Leave a Reply

Your email address will not be published. Required fields are marked *