Lightweight, complex mechanical parts can now be “built to order” quickly and automatically, thanks to Additive Manufacturing (AM) technologies.

AM involves building up a structure by adding material to it layer by layer, with each layer being a precise cross section of the structure. Originally used for rapid prototyping, AM – now based on various laser processes – holds promise for series production of critical components, even in applications as demanding as medical devices and aerospace. (For example:

A recent study proposed providing future long-term space missions with all their medical equipment by means of AM; that way, instead of carrying a fully equipped hospital on board, an AM system would simply produce medical tools as they are needed, from digitally stored templates.)

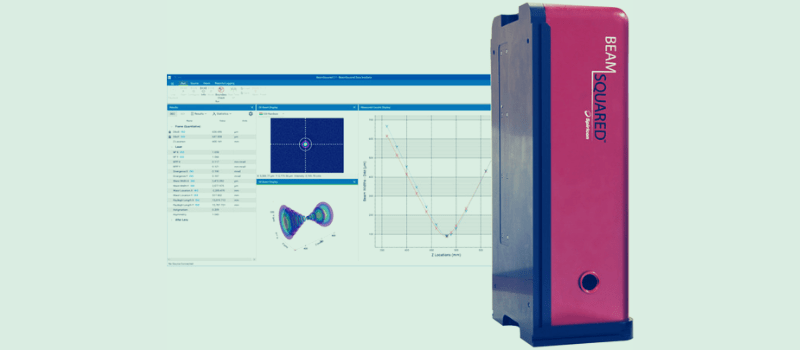

BeamWatch AM – The Industry’s First Non-contact Laser Beam Monitoring System

Ophir offers solutions for monitoring these critical laser parameters.

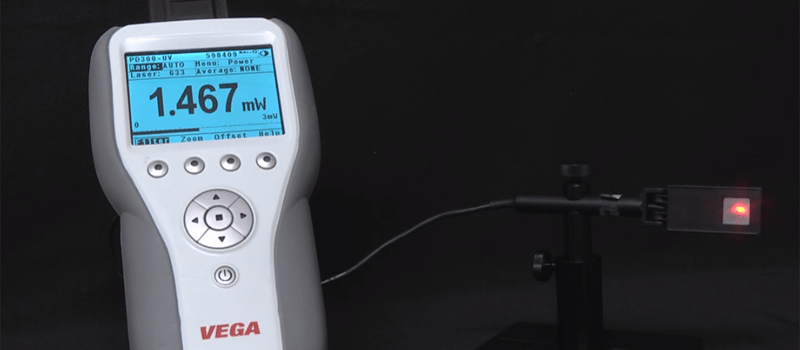

There are instruments for measuring laser beam power and energy, from sensors to meters and PC Interfaces, and even a wireless meter (“Quasar”) for when you can’t have a cable connection with the sensor (such as when measuring inside a chamber).

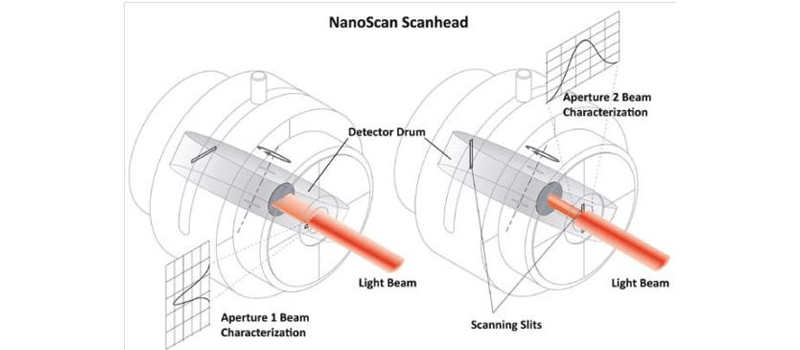

There is a range of solutions for Beam Analysis, including the award-winning BeamWatch AM – the industry’s first non-contact laser beam monitoring system designed specifically for additive manufacturing. It measures key beam size, position, and quality parameters, including focus spot size and beam caustic, and enables real-time measurement of focal shift during laser startup. Watch how BeamWatch AM works in the following video:

Leave a Reply

Your email address will not be published. Required fields are marked *