The Green movement is encouraging the use of energy efficient technologies such as solar cells. This technology has been met with resistance due to its slow return on investment. This is coupled with the challenge of the efficiency of the material used. Reducing the cost of manufacturing solar cells is largely influenced by production efficiencies as well as the type of photovoltaic materials used. Manufacturing efficiencies have been addressed through high speed, nearly fully automated production processes from handling of the panels, deposition of materials, to final packaging. The use of cost effective photovoltaic materials, however, represents a real dilemma. The lower cost deposition materials are less efficient, whereas the higher efficiency materials cost more and can possess carcinogenic elements that are federally controlled.

The solar cell manufacturing community, although addressing more efficient and environmentally safe materials, has concentrated on reducing costs through automated processes. This requires methods that are consistent and reliable. The risk of these operations, however, is that they can produce a large quantity of low cost, high quality material or, just as quickly, they can produce substandard panels.

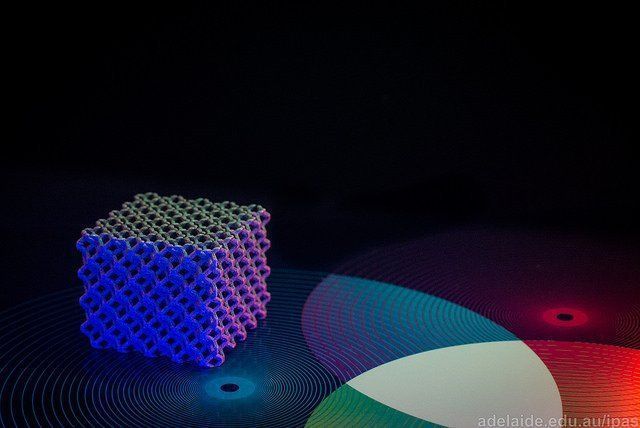

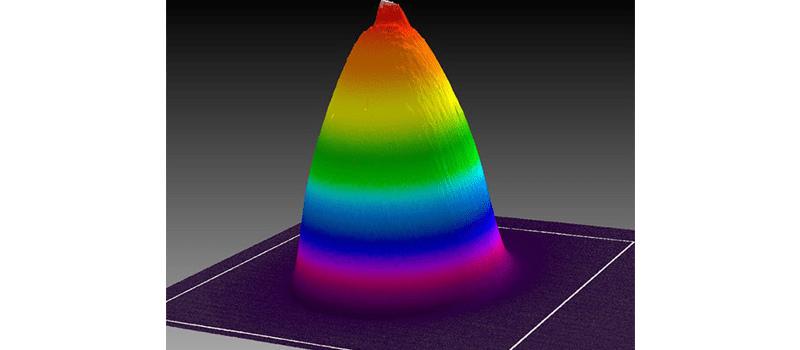

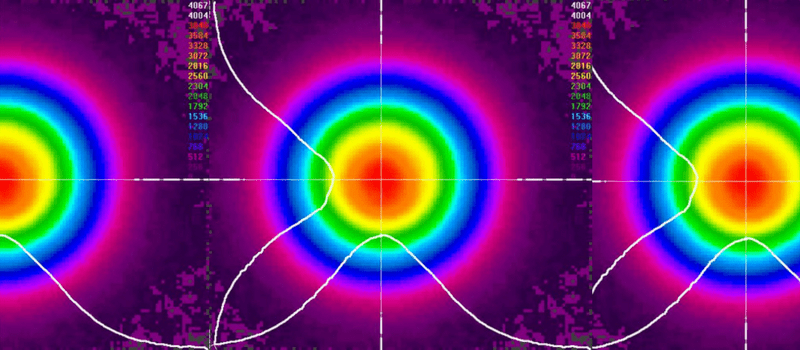

One aspect of the manufacturing process that is critical is the scribing of the photovoltaic material on the individual cells on the large panels. Lasers have proven to be highly reliable, consistent, and predictable in their production results. In this high speed manufacturing arena, lasers can easily keep up with production, are silent to use, and typically contribute to a clean manufacturing environment. Manufacturing lasers requires monitoring the laser beam quality and laser power measurement.

To read the rest of Dick Rieley’s article, please visit the following address:

Lasers and Solar Cell Manufacturing

You might also like to read: Laser beam profiling- a key for “solar revolution”

The hesitation to “go green” largely comes from the high up front costs. That’s why it’s necessary to look at other ways to cut costs. Utilizing laser alignment equipment, companies are able to minimize their downtime, scrap and lost production revenue because they don’t have to rely on outside alignment service companies to come in and align their key production machinery.